Fans and Blowers

NSK Bearings for Different Types of Fans and Drive Systems

Depending on the direction in which the air or gas flows, there are two major types of fans, centrifugal and axial.

Axial fans, the flow goes through the fan, parallel to the fan’s axis.

By contrast, the air or gas enters a centrifugal fan parallel to the drive system's axis (i.e. axially) and is forced out radially by the rotating impeller. There are also various different drive systems: direct drives, belt drives and clutch drives.

NSK bearings run extremely quiet, have a long service life and are very reliable – even in the most demanding ambient conditions characterised by high speeds, contamination, moisture and high temperatures.

NSK can offer a product solution for these tough conditions in various industries.

Operating conditions: difficult environment with factors such as high speeds, high temperatures, contamination from dust and voltage fluctuations

Direct drives are often used for compact fans. The impeller is mounted directly onto the electric motor’s driven shaft, putting a great deal of strain on the bearings in the fan’s electric motors. In these operating conditions, bearings can wear prematurely, leading to downtime and unwanted maintenance costs.

Single-row deep-groove ball bearings are the most common type of bearing used for direct drive systems.

Ceramic Ball Bearings for Fan Motors

Shaft voltage induced predominantly by operation of electric motors on variable frequency drives (adjustable speed drives) creates an environment where electrical discharge current can flow through the bearing. This intermittent current flow can create arc pits that damage the bearing’s internal surfaces and lubrication, causing electrical erosion. A solution to this phenomenon is NSK deep-groove ball bearings with ceramic balls, called ceramic hybrid bearings. These specialty bearings offer protection from current flow through the bearing by using the exceptionally high electrical insulating properties of ceramic balls to create a high resistance barrier between the bearing’s steel rings.

Our innovations:

High-temperature sealed deep-groove ball bearings

Deep-groove ball bearings in different sizes and designs

Operating conditions: high and unevenly distributed loads, high speeds and temperatures, contamination

The electric motor is mounted parallel to the fan’s impeller. In this case, power is transferred via one or more V-belts and pulleys. This design is usually used for medium to large fans. High volume flows and a build-up of heat can cause the bearings to wear out prematurely, resulting in production downtime and high maintenance costs.

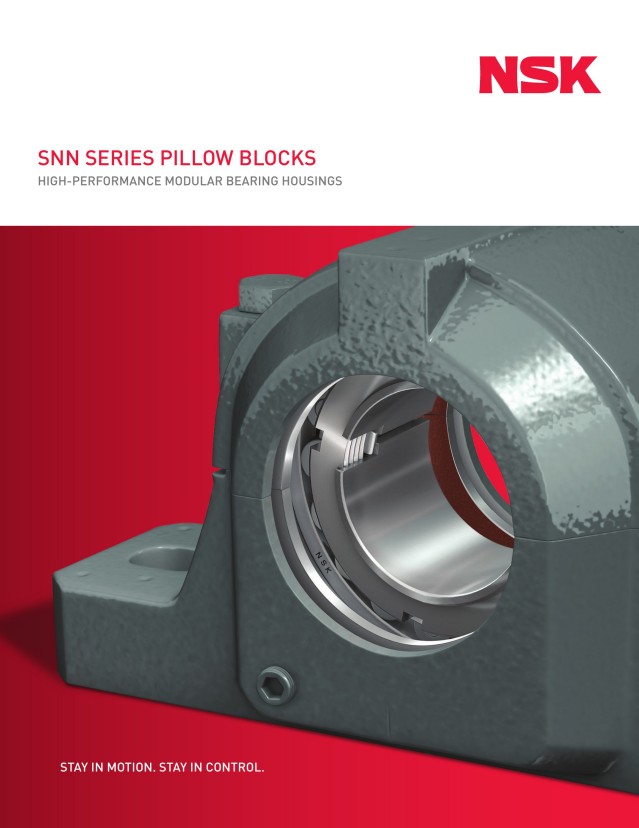

Plummer blocks – the SNN series

The SNN series of plummer blocks from NSK features five different sealing arrangements to meet a range of requirements. The individual components are easy to fit, remove and maintain. Together with advantages such as high rigidity and good heat transfer, the split housings in the SNN series help to reduce costs.

Our innovations:

NSKHPS Spherical Roller Bearings

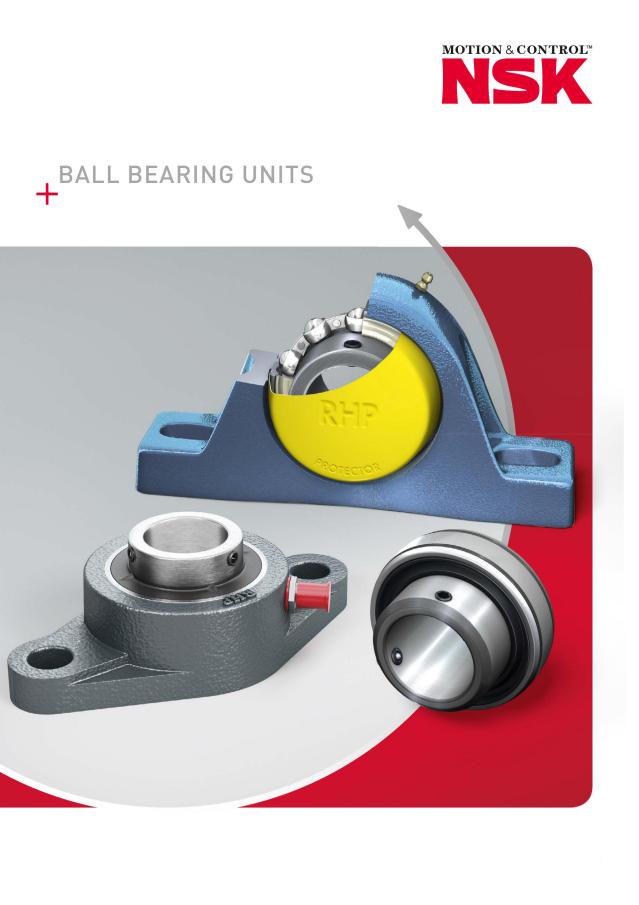

Self-Lube® Units

Self-Lube® HLT Inserts

Self-Lube® Inserts with Flinger Seals

Operating conditions: axial displacement, high and unevenly distributed loads, high speeds, extreme temperatures, contamination

The electric motor is mounted on the same axis as the fan’s impeller. The shafts of the electric motor and the fan are connected by a torsionally flexible coupling. This method of connecting the impeller with the electric drive is mainly used for medium and large fans.

The tough conditions can cause the bearings to wear out prematurely, reducing productivity and driving up maintenance costs.

NSKHPS spherical roller bearings

NSK’s compact HPS spherical roller bearings last twice as long as conventional products, even in extreme operating conditions. Their long service life and high performance reduce maintenance costs and boost productivity.

Our innovation:

SNN series of Plummer blocks