Petrochemical

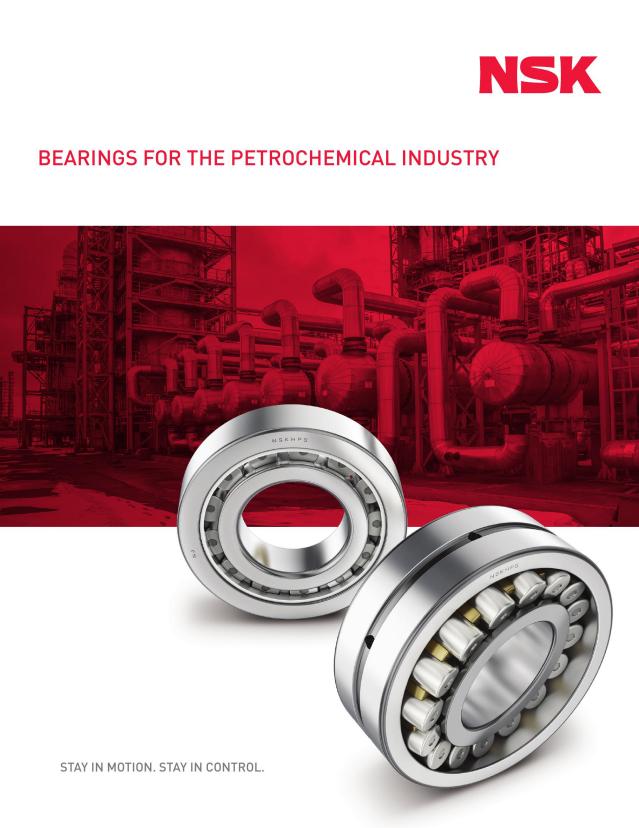

NSK Bearings for the Petrochemical Industry

NSK specialists are in touch with the research and development teams at OEMs that produce components for petrochemical systems. This enables them to develop new bearing solutions at every level of your project.

Centrifugal Pumps

Operating conditions: medium speeds, axial and radial loads

If a process pump fails in a petrochemical plant it can lead to costly downtime. Centrifugal pumps are used to transport liquids at every stage of the process and are among the most sensitive components used in this industry.

Pump applications place a great deal of strain on bearings. The materials used for bearings and bearing cages have to withstand tough conditions. The bearings have to support axial, radial or combined loads, run equally reliably at low and high speeds (1,500 rpm to 3,000 rpm) all while handling different lubrication conditions with ease.

NSKHPS Angular Contact Ball Bearings

The single-row angular contact ball bearings from the NSKHPS series are extremely reliable in compliance with API standards, especially in difficult applications as centrifugal pumps. They exhibit long life, even when exposed to high axial loads.

The special high-strength cage construction makes the bearings in the pumps more resistant to shock loads and vibrations. Thanks to the precisely manufactured guiding surfaces, the noise level is lower than that of conventional bearings.

Our Innovations:

High Capacity Deep Groove Ball Bearings - HR Series

EW Series of Cylindrical Roller Bearings

EM Series of Cylindrical Roller Bearings

BMPC Pump Bearings

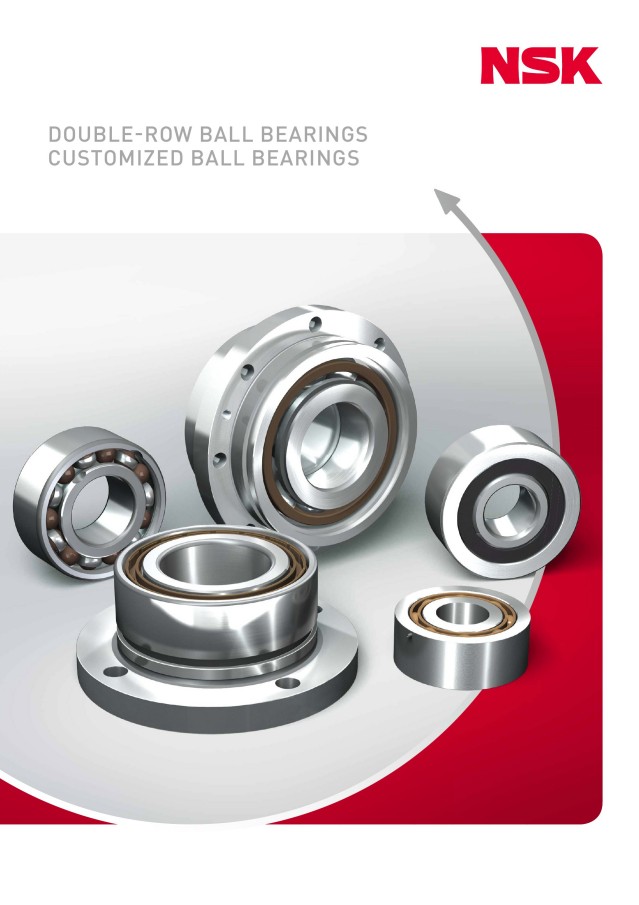

Double Row Angular Contact Ball Bearings

Submersible Pumps

Operating conditions: vertical shaft position, axial loads (bottom bearing), very light radial loads (top bearing)

Submersible pumps are widely used for water and wastewater applications. They have a vertical driving motor which is connected to the impeller at its extremity. The double-row angular contact ball bearing at the bottom must withstand axial and radial loads, while the deep groove ball bearing at the top is only subject to light radial loads. For this, it is important to avoid creep (relative motion) between the outside diameter and housing of the top bearing.

Creep-free bearings for rotating loads

The tight O-rings fixed to the outer ring help to prevent creep once the bearing is subjected to rotating loads. Fitting the bearing is very easy and the housing is reusable.

Our Innovations:

High Capacity Deep Groove Ball Bearings - HR Series

EW Series of Cylindrical Roller Bearings

EM Series of Cylindrical Roller Bearings

NSKHPS Angular Contact Ball Bearings HPS

Double Row Angular Contact Ball Bearings

LNG Pumps

Operating conditions: speed: 1,160 rpm to 3,600 rpm, gas temperature: −196°C to 0°C, predominantly axial loads, insufficient lubrication

Liquefied Natural Gas (LNG) pumps are used to load/unload cryogenic liquids in tanks. Bearings within this application must be able to withstand a liquid gas temperature of −162°C and are partly lubricated by the pumping medium.

Total Quality Solution:

Stainless steel bearings with fluororesin cage

LNG pump bearings from NSK are made from stainless steel, which provides excellent corrosion resistance. They also feature a specific cage made from fluororesin which is self-lubricating even at very low temperatures.

Our Innovations:

High Capacity Deep Groove Ball Bearings - HR Series

NSKHPS Angular Contact Ball Bearings

Double Row Angular Contact Ball Bearings

Roots Blowers

Operating conditions: dry running, medium to high temperatures, vibration

Roots blowers are rotary piston blowers that are often used to transport gas. The gas is carried from the intake side to the exhaust between the lobes of the rotors and the outer wall and compressed by the backflow. This process can generate vibrations, which bearings must be capable to withstand.

Cylindrical roller bearings and double row angular contact ball bearings with steel cages

NSK’s high-performance cylindrical roller bearings and double-row angular-contact ball bearings come with a steel cage that is resistant to heat and wear.

Our Innovations:

Cylindrical Roller Bearings with L-PPS Cage

Angular Contact Ball Bearings with L-PPS Cage

Oil-Injected and Oil-Free Compressors

Operating conditions: oil lubrication, medium to high speeds, medium to high axial and radial loads

Two screws are used to compress gases. The gas enters on the inlet side and flows through the threads while the screws rotate. As the compression space becomes smaller, the gas is compressed. This process requires bearings that can withstand high radial and axial loads and enable precise shaft positioning.

Total Quality Solution:

Angular contact ball bearings & cylindrical roller bearings with special cages

NSK has developed cylindrical roller bearings and angular contact ball bearings specifically for oil-injected screw compressors. The bearings are equipped with NSK's patented L-PPS (linear polyphenylene sulphide) cage that is ideal for use in screw compressors due to its outstanding resistance to heat and wear along high strength and chemical stability.

For oil-free screw compressors, NSK offers angular contact ball bearings, four-point contact bearings and cylindrical roller bearings with outer-ring-guided brass cages. They deliver improved accuracy for performance at high speeds offering excellent precision.

Our Innovations:

Angular Contact Ball Bearings

Cylindrical Roller Bearings

4 Point Contact Ball Bearings with outer ring guided brass cage for oil-free screw compressors

Conveyor Belts

Operating conditions: low speeds, medium to high loads, contaminated environments and high temperatures (for example during the transportation of petroleum coke)

In the petrochemical industry, conveyor belt systems are often used to transport raw materials placing high demands on the bearings’ resistance to factors such as temperatures and contamination.

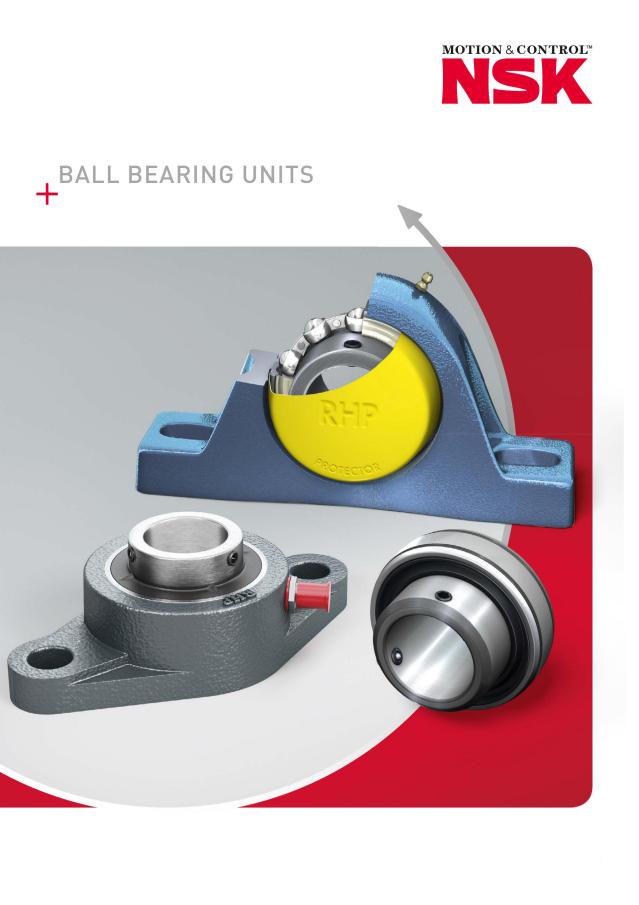

Our Self-Lube® HLT reduce maintenance, downtime and replacement costs in operation at extreme temperatures

Self-Lube® HLT bearing units were developed specially for this application. In addition to preventing contamination, they run at both low and high temperatures from −40°F to + 356°F.

Ventilators

Operating conditions: high loads and speeds, high temperature

Ventilators are needed for a wide range of cooling processes. In most cases, these involve high speeds and temperatures that can reach up to 392°F.

Total Quality Solution:

Our NSKHPS Spherical Roller Bearings are state-of-the-art material technology bearings, suitable for high speeds & loads

NSKHPS spherical roller bearings work precisely and reliably with limiting speeds up to 20% higher than conventional designs. HPS also offers increase in the dynamic load rating by up to 25%. The bearings are wear- and temperature-resistant with long service life making for lower maintenance costs.

Electric Motors

Operating conditions: high temperature, high speeds, vibrations

Electric drives for pumps, compressors, blowers and conveyor belt systems have to withstand high operating temperatures and high speeds.

Total Quality Solution:

High-temperature sealed deep groove ball bearings

This special range has been created to run in dusty environments at high temperatures of up to 300°F. The seals are usually made from fluoroelastomer.